Color matrices are specifications on how camera native color is transformed into something that an end user might like, and ideally will be correct when viewed on a calibrated display. In the past some good work on this topic has been done by Adobe, who published their DNG specification including color matrices. The problem is that camera vendors don’t publish their proprietary postprocessing methods, which leaves us with a problem, how do we postprocess then? Which is good if we want maximum control and flexibility. Now when working in the RAW format we ditch all that postprocessing in favor of RAW sensor data. The pretty images our camera’s output aren’t literally what the camera sensors see, there is a lot of proprietary postprocessing involved. So here we go again, with a vengeance… Why? Since then I’ve pretty much switched to Darktable, and I’ve learned a few things.

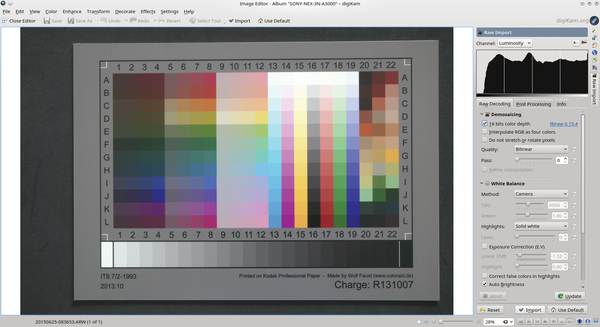

These targets consists of 24 grey fields and 264 color fields in 22 columns: Special targets, implementing the IT8.7/1 (transparent target) or IT8.7/2 (reflective target) standards, are needed for calibrating scanners. It has a very big gamut, slightly bigger than ProPhoto RGB color space.Ĭalibrating all devices involved in the process chain (original, scanner/digital camera, monitor/printer) is required for an authentic color reproduction, because their actual color spaces differ device-specifically from the reference color spaces.Īn IT8 calibration is done with what are called IT8 targets, which are defined by the IT8 standards. This is an IT8 color target made in EGM Laboratories in Barcelona, Spain. Should be transferred with any four-color (cyan, magenta, yellow and black) halftone image files to enable a color transformation to be The purpose of this standard is to specify an input dataįile, a measurement procedure and an output data format to characterize any four-color printing process. IT8.7/3 - 1993 (R2003) Graphic technology - Input data for characterization of 4-color process printing The target that can be manufactured on any color photographic paper and is intended for use in the calibration of a photographic paper/scanner It defines the layout and colorimetric values of Products that are generally used for input to the preparatory process for printing and publishing. It is intended to address the color photographic paper IT8.7/2 - 1993 (R2003) Graphic technology - Color reflection target for input scanner calibration Ĭolor input scanner to be calibrated with any film dye set used to create the target. This standard defines the layout and colorimetric values ofĪ target that can be manufactured on any positive color transparency film and that is intended for use in the calibration of a photographic It is intended to address the color transparency products thatĪre generally used for input to the preparatory process for printing and publishing.

This standard defines an input test target that will allow anyĬolor input scanner to be calibrated with any film dye set used to create the target. IT8.7/1 - 1993 (R2003) - Graphic technology - Color transmission target for input scanner calibration

The information will typically consist of numerical control information used in the manufacture of dies. This standard establishes a data exchange format toĮnable transfer of numerical control information between diecutting systems and electronic prepress systems. IT8.6 - 2002 - Graphic technology - Prepress digital data exchange - Diecutting data (DDES3) The following is a list of the IT8 standards, according to the NPES Standards Blue Book:

0 kommentar(er)

0 kommentar(er)